UPVC/PVC Window and Door Plastic Profile/Door Frame/Ceiling Panel Extrusion Machine

Package Size 350.00cm * 150.00cm * 300.00cm Package Gross Weight 1580.000kg UPVC/PVC window and door profile extrusion m

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | SJSZ-65/132 |

| Plastic Processed | PVC |

| Product Type | Profile Extrusion Molding Machine |

| Feeding Mode | Automatic Feeding |

| Assembly Structure | Separate Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Transport Package | Wooden Packing |

| Specification | Customized |

| Trademark | Trusty |

| Origin | Qingdao |

| HS Code | 84772090 |

| Production Capacity | 30 Set/Month |

Packaging & Delivery

Package Size 350.00cm * 150.00cm * 300.00cm Package Gross Weight 1580.000kgProduct Description

UPVC/PVC window and door profile extrusion machinery PVC ceiling panel /wall panel production line WPC/PVC door frame/door edge extrusion line1.Company ProfileQingdao Trusty Plastic Machinery Co., Ltd. is a professional plastic extrusion equipment manufacturer integrating design, research and development, production and sales.The company's main products are rich, the production technology is mature, and the after-sales service is guaranteed. Products are sold at home and abroad, such as: Brazil, Chile, Mexico, the Philippines, Italy, Russia, Pakistan, Vietnam, India, Algeria, Egypt and other countries.Our company is located in Qingdao, one of the plastic machinery bases in China, where the railway, sea transportation, aviation and other transportation systems are very complete. And it is one of the regions with rapid economic development in the coastal cities.The advantaged geographical conditions have provided great convenience for the development of the company's trade.Our company's main products are: PVC door and window profile production line, WPC wood-plastic profile production line, PVC wall panel production line, PVC/PE/PPR pipe production line, PVC/WPC crust foam board production line, PE/PP/PC hollow sheet production line, PVC roof tile production line and PET packing belt production line, etc. According to customers' needs, to achieve diversified processing customization.Over the years, the company has always adhered to the tenet of "honesty for basis, quality for living, innovation as the theme, and development as the focus", abide by the quality commitment to users, and won the trust of customers.

2.Production Introduction

The PVC door and window profile production line can choose different specifications of conical twin-screw extruders according to different profile sections and molds, and configure the corresponding vacuum calibration table, tractor, cutting machine, stacker and other auxiliary equipment such as PVC hot and cold mixer,PVC miller and Crusher etc...

3.Work flow and detailed information:

| Feeder | • Screw loader feed material into extruder; |

| Extruder | •World famous brand electrical component: Siemens, TE, ABB etc; • High torque gearbox with adopts famour bearing; • Siemens motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface. |

| Die head | • 3Cr13/3Cr17 material• Complete set include extrusion die head, calibrator and cooling tank |

| Calibration table | • Include full set of vacuum and water pump• Width: 240mm• Length: 6000mm• Independent operation panel for easy operation |

| Haul off | • Upper/lower tracks driven separately and speed control by inverter• Fast change type pads for easy operation |

| Cutter | • Lifting saw cutter with adopts double station dust collection system•Synchronous driving by air cylinder or servo motor control |

| Stacker | • Stainless steel304 as touching material• Discharge driving by air cylinder |

| Model | TPM-180 | TPM-300 | TPM-600 |

| Max.width of product(mm) | 180 | 300 | 600 |

| Extruder model | SJSZ-51/105 | SJSZ-65/132 | SJSZ-80/156 |

| Extrusion capacity(kg/h) | 180 | 250 | 350 |

| Motor power(kw) | 22 | 37 | 55 |

| Total length(m) | 18 | 22 | 26 |

5.main composition &photos

| Item | photos |

| SJSZ- 65 Twin Screw Extruder with Automatic Feeding System | |

| Mold | |

| Vacuum Calibrarion Table | |

| Haul-off machine | |

| automatic saw cutter | |

| Stacker | |

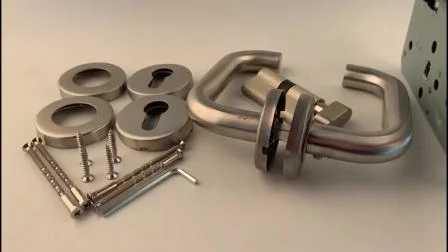

| Final products | |

| other products which this line can produce |

6.FAQ

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5.WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line.

Related Products

-

![Nisen Dl01 UPVC Side Openingsingle Point Door Lock Double Opening]()

Nisen Dl01 UPVC Side Openingsingle Point Door Lock Double Opening

-

![Nisen Sr07 CE UPVC Window Door Roller for Mesh Screen Window Hardware Accessories Screen Window Roller with Wheel Nylon Pulley]()

Nisen Sr07 CE UPVC Window Door Roller for Mesh Screen Window Hardware Accessories Screen Window Roller with Wheel Nylon Pulley

-

![Window Door CNC Double Head Mitre Saw for Aluminum Profile]()

Window Door CNC Double Head Mitre Saw for Aluminum Profile

-

![Double Glazed Washing Glazing Processing Production Line Price Insulated Warm Edge Superspacer Insulating Glass Gas Filling Machine Machinery]()

Double Glazed Washing Glazing Processing Production Line Price Insulated Warm Edge Superspacer Insulating Glass Gas Filling Machine Machinery